Fibers

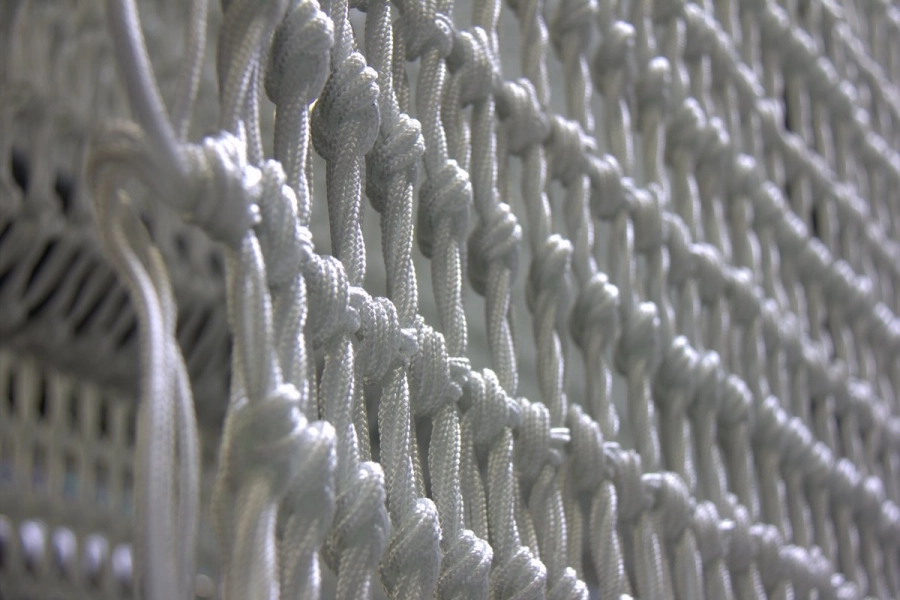

We use many different high tenacity synthetic fibers, or combinations of materials, in our rope and netting products.

The different high tenacity fibers are roughly divided into two groups:

- Conventional

- High Modulus

Most well known conventional materials are Polyamide (nylon), Polyester, Polyethylene and Polypropylene.

High Modulus fibers are much stronger than conventional fibers. Tensile strength and stretch are comparable to those of steel wire, but with a much lower weight. Rope and netting made from these fibers are lighter and easier to handle.

Van Beelen Group works with several High Modulus fibers:

- High Modulus Polyethylene (HMPE), brandname Dyneema®

- Aramids, brandnames Technora®, Kevlar®, Twaron®

- Liquid Crystal Polymer (LCP), brandname Vectran®

Polyamide (Nylon)

Polyamide (nylon) has the highest elasticity of all conventional materials.

Polyester

Of all conventional materials, polyester has relatively the highest coëfficiënt of friction and the highest melting point (250° C).

Polyethylene

Polyethylene is the most common plastic.

Dyneema®

This is DSM's HMPE, High Modulus Polyethylene, branded as Dyneema®

Technora® (Aramid)

Technora® is a para-aramid fiber made from co-polymers.

Vectran® (LCP)

Vectran® is a yarn spun from liquid crystal polymer (LCP). The material has a high strength and rigidity.