+10% fuel saving with Dyneema® gear

A Fishing News International article - November 2014, by Quentin Bates.

10% fuel saving with Dyneema® gear

In 2012 French trawler operator Scapêche approached New Zealand fishing gear company Motueka Nets with an interest in Dyneema® trawl gear and ordered trawls for single rigger Jean Claude Coulon II and for twin rigger La Perouse, with fuel savings made by both vessels with their new gear.

François Theret at Scapêche said that it was partly the Talleys connection that that took them to gear from New Zealand, knowing that the Motueka Nets gear had worked on Talleys vessels fishing in deep water.

Andrew Hope at Motueka Nets said that they were an early adopter of Dyneema® when it appeared for fishing industry uses in the 1990s and they have been making trawls using Dyneema® since 1992.

“The material we used back then was some of the first single knotted Dyneema® netting produced by van Beelen, but the problem at that time was that they cost of the trawls was too high to warrant the extra expense,” he said.

“Fuel costs weren’t an issue then and as the single knotted Dyneema® netting was being made on existing machines set up for PE netting, there were some issues with knot slippage and the material’s abrasion resistance. But since then, everything has changed.”

In the intervening years, fuel costs have become an overriding issue that affects every fishing operator, while there have also been some significant developments in the production of Dyneema® netting.

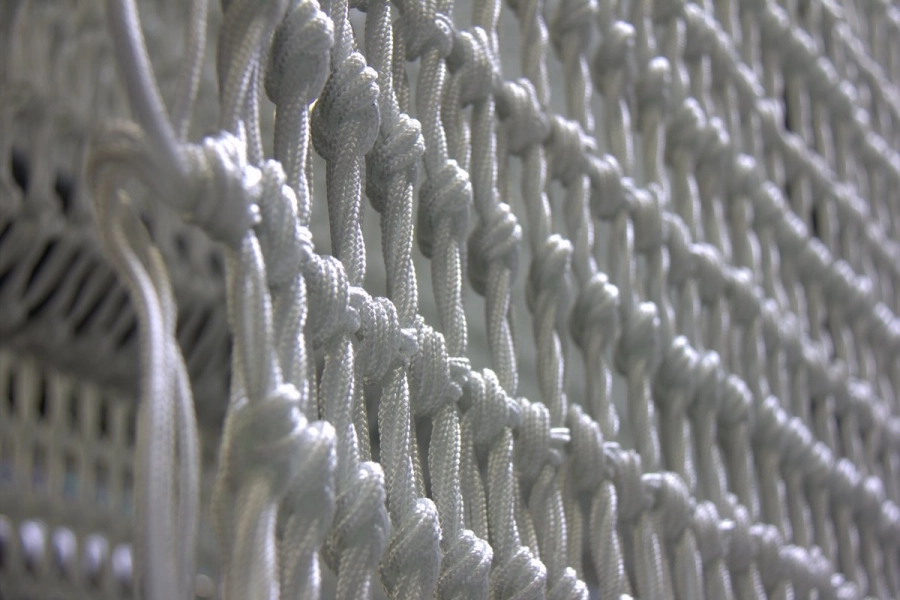

Dyneema® is a super-strength material used for making some ropes, twines and netting, as well as for producing items such as bullet-proof vests and helmets.

“Since 2007 we have had Dyneema® netting made on specially designed machines available to us and those old problems are a thing of the past. Knot integrity is now excellent and the working lifetime of Dyneema® netting has been proved to be many times that of trawls made in much heavier diameter PE twines.”

He said that at the end of 2007 the first complete trawls in this new material were made and the results were highly positive, showing immediate fuel savings, as all the vessels trialling these trawls are fitted with fuel flow meters allowing fuel usage to be monitored precisely.

“Talleys came on board that year and all of their factory vessels now use Dyneema® trawls with an average fuel saving of 10,000 litres per day each. Several Sanford deep water vessels use Dyneema® gear, as do a number of inshore vessels and a couple of Sealord boats. There are some operators who now use exclusively Dyneema® trawls.”

According to François Theret at Scapêche, La Perouse’s gear has been very successful since it was put on board in January last year and has been used to fish for cod, haddock, monkfish, megrims and other mixed fish species on mostly sandy ground,” he said, commenting that La Perouse is not bottom trawling all year as it switches to tuna in the summer, so in two years the Motueka Nets gear has been in use for a total of fourteen months.

“So far they have used half a bale of netting for repairs,” François Theret said.

He commented that the gear is designed around the qualities of the Dyneema® to make the most of the high-strength van Beelen netting while also allowing for the problems that this can also present.

“This netting is so strong that sometimes the gear can be hung up while shooting away with a single mesh caught on a shackle. With standard netting it would just part, but the Dyneema® is so strong that the whole trawl can hang on one mesh.”

La Perouse’s gear has been made with 2.5 mm Dyneema® twine replacing double and single 5mm twine sizes in the original gear. 4mm twine has been used in the new gear in some sections, such as in the guard meshes and at wing ends to provide some protection for the first meshes that are wound onto the net drums.

“The panels are joined using nylon joining rounds,” François Theret said, explaining that this means that if one of the two trawls hits a fastener, then the weaker joining round parts before the Dyneema® netting does, limiting gear damage and making repairs a straightforward business.

“The only problem is the double knots, as repairs take longer and there can be some lost time there. But the gear is very light and easy to work with, and there are so few repairs that this isn’t a real problem for the crews.”

“Fuel consumption is down by at least 10%. Under perfect conditions and in flat calm weather it could go as high as 20%. You need a long trial period for this kind of work to get a reliable figure and Scapêche has been using this for more than a year now,” he said.

While the trials on La Perouse have worked out well, this has been less of a success on board Jean-Claude Coulon for a variety of reasons, but Scapêche is now extending the use of Dyneema® trawls to other trawlers in its fleet.

The 46m Mariette le Roch II is due to be fitted out with a Dyneema® belly for one of its trawls and an other 24m twin-rigger, Bougainville, is now being fitted out with gear similar to La Perouse, which is now also in the process of testing a T90 codend and extension with so far encouraging results.

“This requires a smaller amount of netting, there’s a good flow of water through the gear and the meshes open better,” François Theret said.

“There is minimal loss of target species, quality looks to be better and discards are down by 66%. There is another vessel fishing close to La Perouse that has been trying the same T90 codend and extension, and they have seen practically identical results with one box of discards instead of three, so we will certainly be continuing to evaluate this.”

Scapêche has seen changes to its fleet with the acquisition of four Dhellemmes trawlers earlier this year and a new trawler is due to be delivered next year. The company runs small purse seiners and crabbers, and is also now working on a project to convert 33m trawler Heliotrope to operate as a longliner, fitted out with Fiskevegn gear.

“We want to test this for fuel efficiency, and to see if a longliner can catch enough to make this kind of fishing feasible,” he said.